Ide 29+ 3M Muda Mura Muri

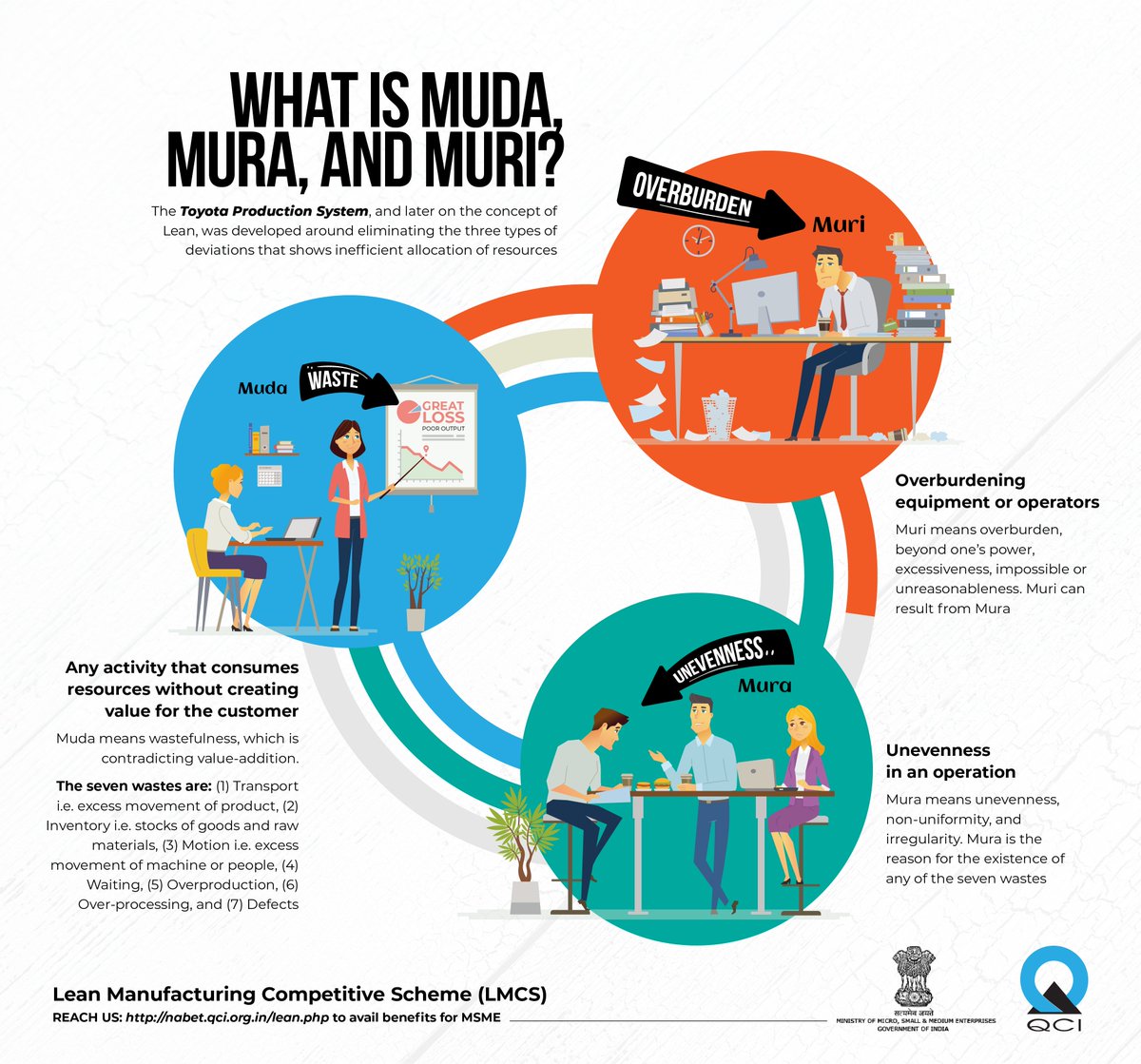

Motion: Unnecessary physical movement of people or equipment. Waiting: Idle time or delays in the workflow. Overproduction: Producing more than what is demanded by the customer. Over processing: Adding more value than necessary to a product or service. Defects: Errors or mistakes that require rework or correction.

7 desperdicios, Mura, Muri, Muda Las 3 mu Lean Solutions

Muda Muri Mura, üretim alanlarında gözlemlenen 3 temel israf kaynağının sınıflandırılmış halidir. Mükemmel bir üretim sisteminden uzaklaştırıp sistemde israfa yol açan aktivite ve durumlar bu.

Muri Mura Muda

The "3 Ms"— muri, mura, muda — is among the most important concepts in lean production. Yet, the Ms are often misjudged. The most common misunderstanding is to see lean only as a method to reduce waste ("muda").Those that start waste-hunting lean projects will not achieve break-through improvements and will never build a culture of continuous improvement.

Muda, Mura, and Muri The Three Wastes Kaizen News

First, let's explain the basic concept of muda, mura, and muri using an example from the Lean Lexicon. This example is on pages 66 and 67 if anyone wants to look it up and check me. It uses the example of a truck carrying some material between stations - between factories, for example. The truck has the capacity of carrying three tons.

Lean manufacturing Muda, Mura và Muri

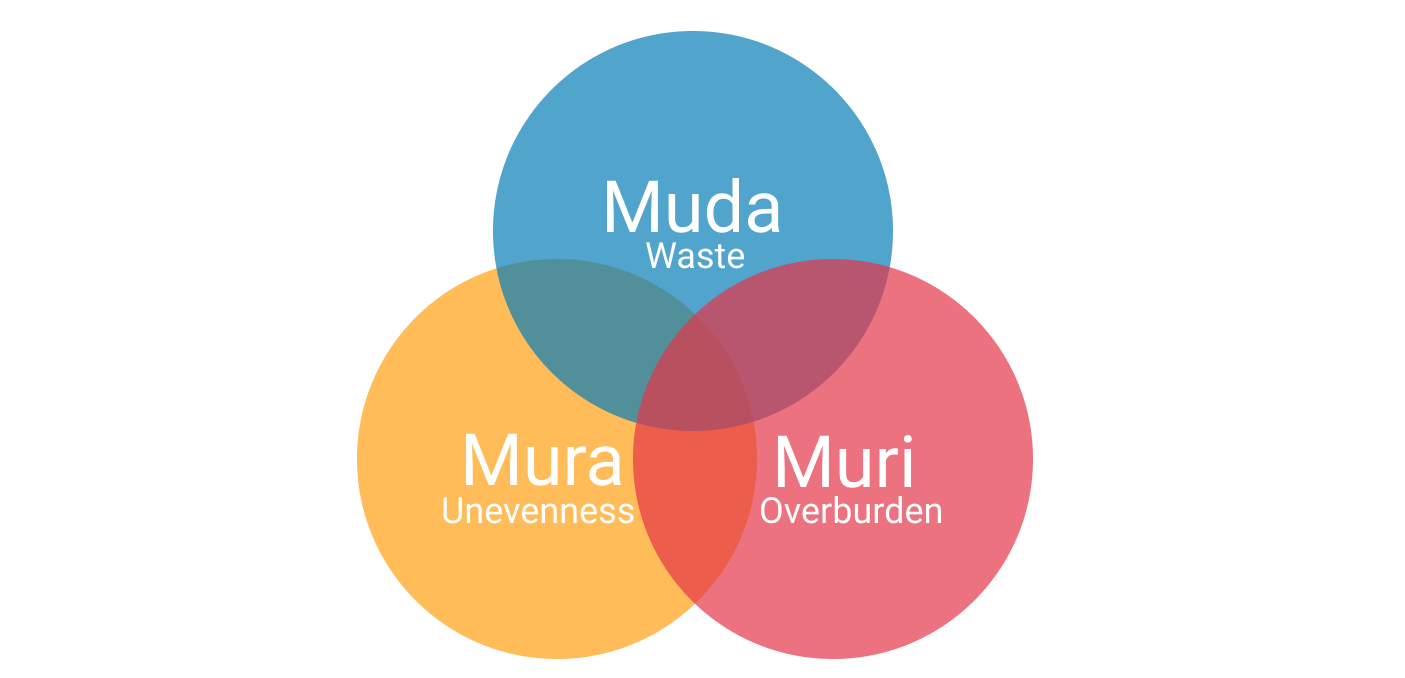

There are two more categories that often go untaught and forgotten. These two are Mura which means Variation or Unevenness, and Muri, which means Overburdened or Over-worked. Muda, Mura and Muri are interrelated and one cannot be removed or influenced without affecting the others. It is paramount for Lean learners to know about all 3 and know.

Processminds Muda mura muri

Muri can be the direct result of Mura, but also from the removal of Muda too. It is the overburden that can be put on employees and machines that may be expected to work at more than 100% capacity. This is unsustainable, and long-term can have devastating effects on employees' health and well-being, and machines pack up far earlier than expected.

Muda muri mura nedir unopro consulting Artofit

Muda means wastefulness. There are 2 types of Muda, Type-1 which can be referred as 'Value enabling activities' and Type-2 which are the 'Non value added activities'. Our aim is to eliminate this Type-2 Muda and minimize Type-1 Muda. There are 8 categories in this Type-2 Muda which are abbreviated as DOWNTIME.

Las 3 Mu's Muda, Mura, Muri

This in turn leads to downtime, mistakes, and backflows - the muda of waiting, correction, and conveyance. The inevitable result is that mura creates muri that undercuts previous efforts to eliminate muda. In short, mura and muri are now the root causes of muda in many organizations. Even worse they put muda back that managers and operations.

Opzoek naar Muri (Overbelasting) Een Handreiking MudaMasters

Remove Muda, Mura and Muri. Lean Manufacturing is about the removal of waste; but not just Muda (non-value adding steps), it is about removing Mura and Muri too. In fact by concentrating on solving Mura and Muri you prevent the creation of Muda. By working on Just in Time (JIT) principles with Heijunka, Kanban and other techniques you enable.

Lean Manufacturing Blog Trang 10 trên 10 Đầu tư vào tri thức đem lại lợi nhuận cao nhất.

Muda, Mura, and Muri are terms often used together in the Toyota Production System (and called the Three Ms) that collectively describe wasteful practices to be eliminated. An Introduction to Muda, Mura, and Muri Watch on Muda Any activity that consumes resources without creating value for the customer.

Muda, Mura and Muri All you need to Know

Looking at it collectively When examining business processes for inefficiencies, it is important to take into consideration the presence of all three - Muda, Mura, and Muri. They are all interrelated and are all considered wastes. One does not look for Muda alone and hope to solve a process problem completely.

Muda muri mura nedir unopro consulting Artofit

Toyota has developed its production system around eliminating three enemies of Lean: Muda (waste), Muri (overburden) and Mura (unevenness) (Liker, 2004). Muda is the direct obstacle of flow. As written below, there are 8 distinctive types of muda which all lead to waiting times, and therefore longer lead times in a process. Simply taking out the muda does not work.

MUDA, MURA, MURI eliminujte plytvanie vo vašom podniku raeda.sk

Muda, Mura, and Muri are concepts rooted in the Toyota Production System, also known as Lean Manufacturing. Developed by Toyota in the 1940s, this system revolutionized the manufacturing industry by emphasizing the elimination of waste to achieve operational excellence. The Three Ms serve as a guide for identifying different types of waste and.

Muda, Mura, Muri I came, I saw, I eliminated? Consider

The terms muda, mura, and muri (waste, unevenness, and overburden) are actually not an invention by Toyota. They were used in Japanese martial arts long before Toyota. In martial arts, any excess movement in combat is a waste, since it tires the athlete and leaves him open for an attack. Similarly, any uneven or unnatural movement or thought.

What is MURI, MURA, MUDA

Muri means overburden, beyond one's power, excessiveness, impossible or unreasonableness. Muri can result from Mura and in some cases be caused by excessive removal of Muda (waste) from the process. Muri also exists when machines or operators are utilized for more than 100% capability to complete a task or in an unsustainable way.

Muda, Muri, Mura… Excellence Opérationnelle

Muda, 3M'in içinde en önemlisiymiş gibi lanse edilerek tüm odaklar (Muda'nın üzerine yoğunlaşılarak çözülmeye başlanır. Oysa ki, iş yerlerinde Mudaların olması daha çok Muri ve Muraların etkisi sonucudur. Yalın düşünce uygulamalarında 3M (Muri, Mura, Muda) sıralaması nasıl olmalıdır? Sıralamasına bakalım ve biraz tanıyalım.